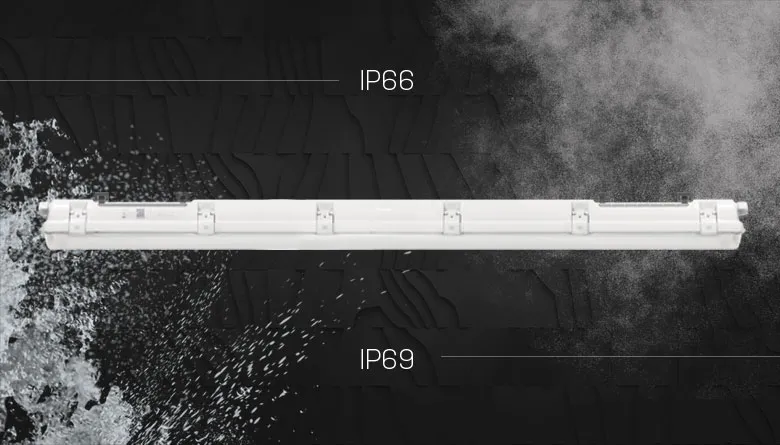

Our INNOVA and NANOTTICA fittings are rated at IP66/IP69. What does it mean?

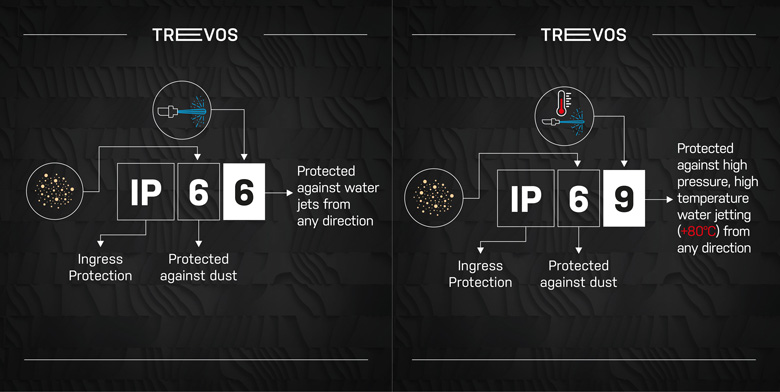

IP66/IP69 is a designation against the ingress of dust and water

The first digit of the protection marking indicates the degree of protection against dust ingress, the second digit indicates protection against water ingress.

Beside IP66, our INNOVA and NANOTTICA fixtures are also tested for IP69 ingress protection. As degrees of protection 6 and 9 are not interchangeable, the marking for multi-purpose application must be used: IP66/IP69 indicating both different types of protection.

How are our luminaires tested for dust and water protection?

Light fixtures rated at IP66 are tested for protection against powerful water jets from any direction (see below for more about this test). These fittings are suitable for a range of industrial applications, as well as for warehouses, car parks and corridors.

An IP69-rated light fitting has passed a high pressure, high-temperature spray down test (see below for more about this test). This makes it a perfect choice for demanding environments with stringent hygiene and technical standards, such as in the food industry and research.

INNOVA IP66/IP69 product family

NANOTTICA IP66/IP69 product family

An ingress protection test, or IP test, is one of the high-priority industrial lighting certification and compliance tests required by the IEC standards. The following TREVOS luminaires are IP66 and/or IP69-rated: NANOTTICA, INNOVA, FUTURA, PRIMA, ALUMAX, TREX.

First, a dust test for first characteristic numeral IP6 is performed under EN 60598-1(9)(2)(1). A luminaire is tested in a dust chamber in which talcum powder is maintained in suspension by an air current. The chamber contains 2 kg of talcum powder with a prescribed grain size for every cubic metre of its volume. The luminaire is switched on and operated until operating temperature is achieved. Whilst still operating, it is then placed in the dust chamber in its normal operating position and the fan/blower causing the talcum powder to be in suspension is switched on. After 1 minute, the luminaire is switched off and allowed to cool for 3 hours whilst the talcum powder remains in suspension.

Luminaires to be tested under EN 60529 are subjected to the same test as above; however, the latter standard also calls for the luminaire to have no more than 2 kPa applied to the inside of the enclosure by the vacuum pump in the dust chamber to test for dust ingress protection. The vacuum hose enters the enclosure through the wire bushing. As the luminaire is sealed and therefore the requirements for the minimum air exchange in it are not met, the duration of the test is set by the standard to 8 hours. The talcum powder keeps circulating in the dust chamber throughout this time. A test under this standard is required for fittings intended for explosive atmospheres by EN 60079-0.

Neither of the standards cited above allow ingress of dust into the enclosure during the test. Evaluation is visual and is performed after the luminaire has been thoroughly cleaned and then opened.

Luminaires protected against powerful water jets – the second digit of the IP code is 6

The test is performed in the same way, regardless of whether it is in accordance with EN 60598-1 or EN 60529. The first step is the same as in the dust test: the fitting is operated until operating temperature is achieved. Immediately after achieving operating temperature the luminaire is switched off and exposed to water jets as prescribed in the relevant provisions of the standard.

Basic test requirements are as follows:

- Inside diameter of standard spray nozzle: 12.5 millimetres

- Water volume: 100 litres per minute, water projected in powerful jets against the enclosure from any direction

- Test duration: at least 3 minutes

- Distance of nozzle from luminaire: 3 metres

No water ingress into the enclosure is allowed during the test. Evaluation is performed after the test has been completed and the surface of the fitting has been thoroughly dried. Condensation may occur on the inside of the enclosure due to the difference in temperatures. This is not to be confused with water ingress and considered as a failure to comply with the test requirements.

Luminaires protected against high-pressure high-temperature spray downs – the second digit of the IP code is 9

This high-pressure high-temperature spray down test was only introduced into EN 60598-1 standard by its 7th edition; however, it is performed in accordance with EN 60529/A2.

It consists in the luminaire being exposed to spray downs as defined in 14.2.9. of the standard produced by a standard test nozzle. As the luminaire is regarded by the standard as a large enclosure, the test requirements are as follows:

- Water temperature: 80 ± 5 °C

- Distance of the standard nozzle from the sample: 175 ± 25 millimetres, spraying from any direction

- Test duration: at least 3 minutes

- The impact force of the water jets produced by the test nozzle must be verified for the test. The water flow rate should be set to 15 ± 1 litres per minute to ensure the distribution force of water ranges from 0.9 to 1.2 N (water temperature during evaluation to be 20 ± 5 °C).

No ingress of water into the luminaire is permitted during the test.

The IP rating of each light fitting is based on which of the requirements stipulated by the applicable standards it meets. If a luminaire features an IP66 label, it means that it meets the requirements of both the dust test (first digit is 6) and the powerful water jet test (second digit is 6).